Liquid / Gas Strainers - Review

Liquid / Gas Strainers are used within a fluid / hydraulic system to trap or strain-out particulate material from the system piping and components. Strainers are available in many configurations and sizes. Typical strainer configurations are; in-line, tee type, y strainers, conical, basket duplex and simplex.

Liquid / gas strainers are installed in series or in-line of the fluid system pipe either at the output and/or input pipe to the pressure source or end item process. The two most common types types of strainers are basket and Y type. Y strainers are typically used within gas systems, where cleaning requirements are much less than liquid systems. Basket type strainers are generally used within liquid systems. Basket type strainers are of higher capacity than Y-strainers, tee type strainers and produce less pressure drop. Basket type strainers must be installed with the basket down in an “upside down”

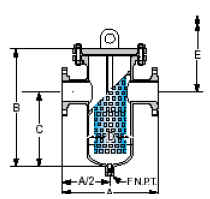

Simplex Liquid / Gas Basket Strainers

Simplex Type Basket Strainer |

Simplex strainers are used in application where straining redundancy is not required. Typical unit will include access to the strainer element for cleaning or replacement. Flange interface may be bolted, pvc bond type, of a simple nipple hose connection

Duplex Liquid / Gas Basket Strainers

In duplex type Liquid / Gas basket strainers, fluid flows through one of the two strainer chambers. When the basket strainer element within one of the chambers in use becomes clogged or full, a mechanism within the chamber changes, preventing fluid flow into that clogged chamber. The mechanism within the parallel chamber will then open and the system flow is diverted to a clean strainer basket. This simplifies maintenance and ensures system operation continues.

Duplex Type Strainers

Click on above image to enlarge

Liquid / Gas strainers are designed for use within many applications and industries, such as: marine, industrial process ( heat exchangers, condensers, and pumps), paint, ink, electric utilities, food processing, and water handling.