Thermal Oxidizers Review

Thermal Oxidizers Review

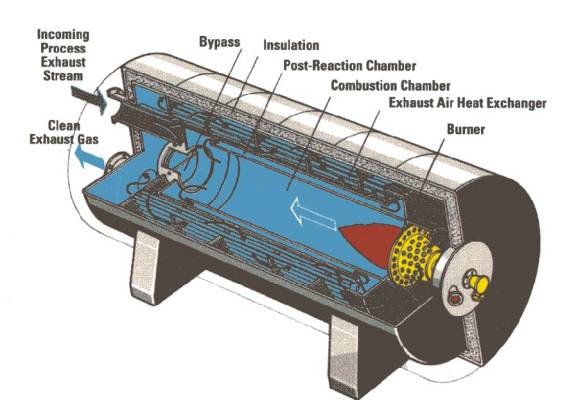

Thermal oxidizers are used within industry to modify product and process gas emissions into environmentally safe gasses. Typical thermal oxidizers process contaminants by first preheating the gasses, then passing the gasses through a burner at a controlled and optimal temperature. When the gasses are subjected to the optimal temperature, the pollutants are converted into environmentally safe gasses, such as water, or carbon dioxide. Typically, the treated gasses are thermally recycled to assist in the thermal oxidation process. The cleaned gasses are then exhausted into the atmosphere.

Thermal oxidizers are typically one of two types, recuperative or regenerative. Recuperative thermal oxidizers may use a catalytic material within the gas stream to assist in converting the gasses into environmentally safe gasses. Regenerative thermal oxidizers typically rely exclusively on gas conversation by utilizing optimal or controlled temperature methods.

Industry processes which utilize thermal oxidizers are: printing, curing, paint spraying, coating processes, and laminating.

Courtesy UCDavis

University od California