Related Resources: calculators

Bolt Torque and Clamping Force Formulas and Calculator per. JIS B 1083

Torque Design Menu

Torque Conversion Calculator

Strength of Materials

Bolt Preload Equations

Fastener Relation Between Torque and Clamping Force Formula and Calculator per. JIS B 1083

Preview Bolt Relation Between Torque and Clamping Force Formula and Calculator per. JIS B 1083

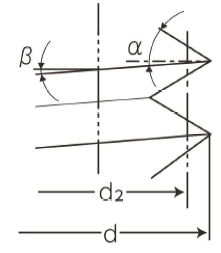

Bolt Thread nomenclature Figure 1

Relationship between the applied tightening torque and bolt preload Ff

Equation 1

Tf = Ts + Tw = K · Ff · d

Where:

Tf = fastener tightening torque

Tw = bearing surface torque

Ts = shank (threaded) portion torque

K = Torque coefficient (Eq. 2)

d = nominal diameter of the screw thread

Equation 2

K = 1 / ( 2 · d ) ( P / π + µs · d2 · sec α' + µw · Dw )

Where:

P = screw thread pitch

µs = coefficient of friction between threads

d2 = pitch diameter of the thread

µw = coefficient of friction between bearing surfaces

Dw = equivalent diameter of the friction torque bearing surfaces

α' = flank angle

at the ridge perpendicular section of the thread ridge

Equation 3

tan α' = tan (α) · cos(β)

Where:

α = thread half angle (30°, for example),

β = thread helix, or lead, angle.

Equation 4

β = l / ( 2πr )

Where:

r = thread radius (i.e., one-half

the nominal diameter d)

l = thread lead = P

When the bearing surface contact area is circular,

Equation 5

Dw = 2/3 · ( Do3 - Di3 ) / ( Do2 - Di2 )

Where:

Do = outside diameter bearing surface

contact area

Di = inside diameter bearing surface

contact area

Torques attributable to the threaded portion of a fastener, Ts, and bearing surfaces of a joint, Tw, are as follows:

Equation 6

Ts = Ff / 2 ( P / π + µs · d2 · sec α' )

Equation 7

Tw = ( Ff / 2 ) · µs · Dw

Where:

Ff, P, µ, d2, α′, µs, and Dw are as previously defined.

Equation 8

Tfy = K · Ffy · d

where the yield clamping force Ffy is given by:

Equation 9

Ffy = σy · As / { 1 + 3 [ 2 / dA ( P / π + µs · d2 ·sec(α') ) ]2 }

Where:

σy = yield point or proof stress of the bolt

As = stress area of the thread

dA = diameter of a circle having an area equal to the stress areaof the thread

Other varibles have been identified previously

Equation 10

dA = ( 4 As / π )1/2

Torque Coefficients K for Metric Hexagon Head

Bolt and Nut Coarse Screw Threads

JIS B 0205 (ISO 724) thread standard

Coefficient of Friction K |

||||||||||

Between Threads, µs |

Between Bearing Surfaces, µw |

|||||||||

0.08 |

0.10 |

0.12 |

0.15 |

0.20 |

0.25 |

0.30 |

0.35 |

0.40 |

0.45 |

|

0.08 |

0.117 |

0.130 |

0.143 |

0.163 |

0.195 |

0.228 |

0.261 |

0.293 |

0.326 |

0.359 |

0.10 |

0.127 |

0.140 |

0.153 |

0.173 |

0.206 |

0.239 |

0.271 |

0.304 |

0.337 |

0.369 |

0.12 |

0.138 |

0.151 |

0.164 |

0.184 |

0.216 |

0.249 |

0.282 |

0.314 |

0.347 |

0.380 |

0.15 |

0.153 |

0.167 |

0.180 |

0.199 |

0.232 |

0.265 |

0.297 |

0.330 |

0.363 |

0.396 |

0.20 |

0.180 |

0.193 |

0.206 |

0.226 |

0.258 |

0.291 |

0.324 |

0.356 |

0.389 |

0.422 |

0.25 |

0.206 |

0.219 |

0.232 |

0.252 |

0.284 |

0.317 |

0.350 |

0.383 |

0.415 |

0.448 |

0.30 |

0.232 |

0.245 |

0.258 |

0.278 |

0.311 |

0.343 |

0.376 |

0.409 |

0.442 |

0.474 |

0.35 |

0.258 |

0.271 |

0.284 |

0.304 |

0.337 |

0.370 |

0.402 |

0.435 |

0.468 |

0.500 |

0.40 |

0.285 |

0.298 |

0.311 |

0.330 |

0.363 |

0.396 |

0.428 |

0.461 |

0.494 |

0.527 |

0.45 |

0.311 |

0.324 |

0.337 |

0.357 |

0.389 |

0.422 |

0.455 |

0.487 |

0.520 |

0.553 |

Torque Coefficients K for Metric Hexagon Head

Bolt and Nut Fine-Screw Threads

JIS B 0207 thread standard (ISO 724)

Coefficient of Friction K |

||||||||||

Between Threads, µs |

Between Bearing Surfaces, µw |

|||||||||

0.08 |

0.10 |

0.12 |

0.15 |

0.20 |

0.25 |

0.30 |

0.35 |

0.40 |

0.45 |

|

0.08 |

0.106 |

0.118 |

0.130 |

0.148 |

0.177 |

0.207 |

0.237 |

0.267 |

0.296 |

0.326 |

0.10 |

0.117 |

0.129 |

0.141 |

0.158 |

0.188 |

0.218 |

0.248 |

0.278 |

0.307 |

0.337 |

0.12 |

0.128 |

0.140 |

0.151 |

0.169 |

0.199 |

0.229 |

0.259 |

0.288 |

0.318 |

0.348 |

0.15 |

0.144 |

0.156 |

0.168 |

0.186 |

0.215 |

0.245 |

0.275 |

0.305 |

0.334 |

0.364 |

0.20 |

0.171 |

0.183 |

0.195 |

0.213 |

0.242 |

0.272 |

0.302 |

0.332 |

0.361 |

0.391 |

0.25 |

0.198 |

0.210 |

0.222 |

0.240 |

0.270 |

0.299 |

0.329 |

0.359 |

0.389 |

0.418 |

0.30 |

0.225 |

0.237 |

0.249 |

0.267 |

0.297 |

0.326 |

0.356 |

0.386 |

0.416 |

0.445 |

0.35 |

0.252 |

0.264 |

0.276 |

0.294 |

0.324 |

0.353 |

0.383 |

0.413 |

0.443 |

0.472 |

0.40 |

0.279 |

0.291 |

0.303 |

0.321 |

0.351 |

0.381 |

0.410 |

0.440 |

0.470 |

0.500 |

0.45 |

0.306 |

0.318 |

0.330 |

0.348 |

0.378 |

0.408 |

0.437 |

0.467 |

0.497 |

0.527 |

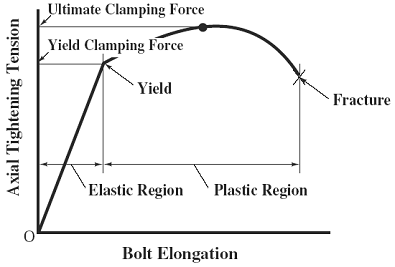

Relationship between Bolt Elongation and Axial Tightening Tension

Related:

- Torque Wrench Adapter for Reduced Arm Equation and Calculation

- Torque Clamp Force Calculator

- Stud Preload Calculator

- Bolt Preload Tension Equation and Calculator

- Bolt Preload Tension Force Calculator

- Torque vs Tension Bolts Table Chart SAE J429 Bolts

- Bolt Multiple Diameters Change of Length Under Axial Force Formula and Calculator