Related Resources: calculators

Critical Speed Ball Screw and Lead Screws Formulas and Calculator

Machine Design Formulas and Calculators

Gear Design and Engineering Data

Critical Speed Ball Screw and Lead Screws Formulas and Calculator:

The critical speed is the lowest rational speed that a shaft is in resonance.

nc = fc ( dr / Lc2) 107

Where:

nc = critical speed (rpm)

dr = root diameter of screw (mm)

fc = factor based on end speed support bearings

Lc = unsupported length of screw (mm)

Typical fc factor (see Ball Screw Design Equations for related images):

Fixed - free = 3.4

Supported - supported = 9.7

Fixed - supported = 15.1

Fixed - fixed = 21.9

Characteristic speed

DN = do nmax

and

nmax = DN / do

DN = characteristic speed (rpm)

do = nominal diameter of the screw (mm)

nmax = maximum allowable rotational speed (typical 60,000 - 150,000 mm/min)

Typical DN values for ball screw return designs are:

- 76,200 mm-RPM (3,000 in-rpm) for Standard external return systems

- 133,300 mm-RPM (5,250 in-rpm) for external returns systems with solid deflectors

- 140,000 mm-RPM (5,510 in-rpm) for internal transfer designs

DN value can be used to deteremine the maximum speed of the screw assembly except for small diameter screws.

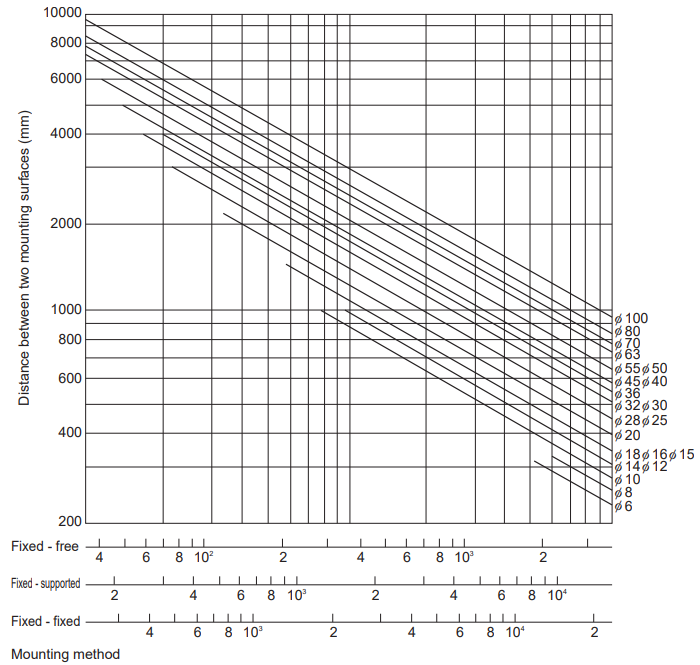

Typical Permissible Rotaional Speed Diagram

(Click on image to enlarge)

Related: