Related Resources: civil engineering

Plywood Minimum Bend Radius Design Considerations

Plywood Minimum Bend Radius Design Recommended

Plywood, after softening, may be bent on a cold ventilated form. The part should be allowed to dry completely on the form. When bending plywood, drying may be hastened by laying a piece of coarse burlap over the radius bending form. To speed drying, a fan may be used to circulate air around the formed Plywood part.

In bending pieces of small radii or to speed up the bending of a large number of parts of the same curvature, it may be necessary to use a heated bending form. The surface temperature of this form may be as high as 149 °C (300 °F), if necessary, without danger of damage to the plywood. The plywood should be left on the heated form only long enough to dry to room conditions.

|

At 90° to Face Grain

|

|

At 0° to 45° Face Grain

|

|

At 90° to Face Grain

|

|

At 0° to 45° Face Grain

|

|

Plywood

Characteristics |

10% Moisture

Bent on Cold Mandrels |

Thoroughly Soaked

in Hot Water, Bent on Cold Mandrels |

|||

|

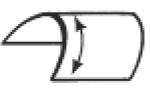

Figure 1

|

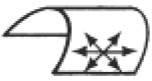

Figure 2

|

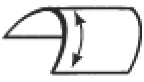

Figure 3

|

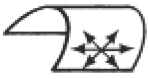

Figure 4

|

||

|

Thickness

(inches) |

Number of Layer

Plies |

Minimum Bend Radius

(inches) |

|||

|

.035

|

3

|

2.0

|

1.1

|

0.5

|

0.1

|

|

.070

|

3

|

5.2

|

3.2

|

1.5

|

0.4

|

|

.100

|

3

|

8.6

|

5.2

|

2.6

|

0.8

|

|

.125

|

3

|

12.0

|

7.1

|

3.8

|

1.2

|

|

.155

|

3

|

16.0

|

10.0

|

5.3

|

1.8

|

|

.185

|

3

|

20.0

|

13.0

|

7.1

|

2.6

|

|

.160

|

5

|

17.0

|

11.0

|

6.0

|

2.0

|

|

.190

|

5

|

21.0

|

14.0

|

7.0

|

3.0

|

|

.225

|

5

|

27.0

|

17.0

|

10.0

|

4.0

|

|

.250

|

5

|

31.0

|

20.0

|

12.0

|

5.0

|

|

.315

|

5

|

43.0

|

28.0

|

16.0

|

7.0

|

|

.375

|

5

|

54.0

|

36.0

|

21.0

|

10.0

|

Reference:

Federal Aviation Administration,

Acceptable Methods, Techniques and Practices Aircraft Inspection and Repair.

Advisory Circular AC 43.13-1B

Related

- Laminated Plywood CNC Speeds and Feeds Table

- Soft Plywood CNC Speeds and Feeds Table

- Pilot Hole Sizes In Plywood

- Wood Screw Pullout Withdraw Resistance Force Formulae and Calculator

- Lag Screws in Wood Pullout Resistance Force Formulae and Calculator

- Allowable Loads and Stress in Wood Formulae and Calculator

- Wood Lap Joint Glue Strength Design Equations and Calculator

- Wood Nail Pullout Withdraw Resistance Force Formulae and Calculator

- Pressed Drift Pin Bolts in Wood Force Formulae and Calculator

- Wood Butt Joint Glue Strength Formulae and Calculator

- Wood Glue Bevel Joint Strength Equations and Calculator

- Holding Power of Wood Screws