Related Resources: Manufacturing

Feature Based Cost Estimation Extruded Parts

NOTE: Refunds are not awarded after excel files have been downloaded - review your membership agreement for details.

Design for Manufacturability and Assembly DFM DFMA

Feature Based Cost Estimation of Extruded Parts Excel Spreadsheet Calculator and Thesis Document

Note: Accessing this resource requires an active Premium Annual Membership with Engineers Edge

Download:

- Feature Based Cost Estimation of Extruded Parts Excel Spreadsheet Calculator

- Feature Based Cost Estimation of Extruded Parts

The manufacturing industry is one of the main drivers of today's global economy, representing approximately 20% to 30% of the value of all goods and services produced in industrialized countries [1]. The product design process is a critical activity for manufacturers, as it has been estimated that about 70% to 80% of the cost of product development and manufacture is determined at the initial design stages [1]. Ironically, in most manufacturing organizations, design and manufacture are separate areas and information has to be passed across the boundaries, often resulting in costly design iterations, long product development cycle times and high manufacturing costs [2]. Thus, modern approaches like Concurrent Engineering (CE) and Design for Manufacture (DFM) represent very attractive options for successfully integrating design and manufacturing functions in the industry, with the objective of minimizing the time and costs involved in taking a product from the conceptual design phase to production and introduction into the marketplace.

From a typical engineering perspective, every single product must be designed to perform a specific function in an efficient way and withstand certain operating conditions without failure during its entire useful life. Historically, design engineers have tended to focus on such technical aspects only, leaving the business part of the process to “other people” and neglecting important “downstream” considerations that affect the usability and cost of the product during its lifetime [3]. In response, Westney [4] states that “successful engineers today understand that technical work is merely part of a cost-driven business process. In most companies, the successful project is not necessarily the one that has the most sophisticated design, but more likely it is the one that makes the most money. Modern engineers know that a project that was a technical success will be judged a business failure if costs are not analyzed and controlled”.

Excel Spreadsheet includes the following:

- FBC Hot Extrusion

- Cost Summary

- Auxiliary Calculations

- Press Selection Solver

- Machine Database

- Raw Material Database

TOS Related Document:

CHAPTER 1: INTRODUCTION AND STATE OF THE ART .................................................................... 1

1.1

Introduction .......................................................................................................................... 1

1.2

Extrusion Process Background and State of the Art ............................................................. 2

CHAPTER 2: MANUFACTURING COST ESTIMATION FUNDAMENTALS ......................................... 12

2.1

The Importance of Manufacturing Cost Estimation ........................................................... 12

2.2

Manufacturing Cost Analysis Approach .............................................................................. 13

CHAPTER 3: ALUMINUM HOT EXTRUSION PROCESS .................................................................... 19

3.1

Why Aluminum Hot Extrusion?........................................................................................... 19

3.2

Billet Preheating .................................................................................................................. 19

3.3

Extrusion ............................................................................................................................. 21

3.4

Quenching ........................................................................................................................... 22

3.5

Stretching ............................................................................................................................ 23

3.6

Cutoff ................................................................................................................................. 24

3.7

Artificial Aging ..................................................................................................................... 25

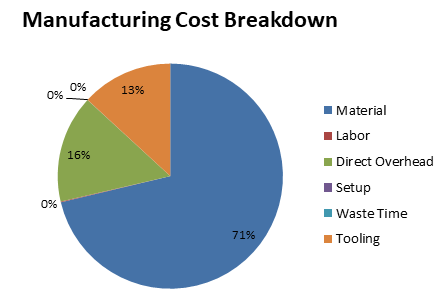

CHAPTER 4: EXTRUSION RECURRING COSTS ESTIMATION ........................................................... 27

4.1

Press Selection .................................................................................................................... 27

4.2

Cycle Time ........................................................................................................................... 45

4.3

Labor and Overhead Costs .................................................................................................. 52

4.4

Material Cost ....................................................................................................................... 53

4.5

Other Direct Costs ............................................................................................................... 58

4.6

Piece Part Cost .................................................................................................................... 61

CHAPTER 5: EXTRUSION NON-RECURRING COSTS ESTIMATION .................................................. 62

5.1

Extrusion Tooling Background ............................................................................................ 62

5.2

Tooling Cost Estimation Approach ...................................................................................... 75

5.3

Vital Xs Screening and Selection ......................................................................................... 76

5.4

Experiments Planning and Results ...................................................................................... 81

5.5

Regression Analysis ............................................................................................................. 84

CHAPTER 6: COST MODEL VALIDATION ........................................................................................ 97

6.1

Cost Model Validation Approach ........................................................................................ 97

6.2

Overhead Upcharge Calibration ......................................................................................... 97

6.3

Recurring Costs Model Validation .................................................................................... 104

CHAPTER 7: CONCLUSIONS ......................................................................................................... 112

7.1

Thesis Research Conclusions............................................................................................. 112

7.2

Future Work Recommendations ....................................................................................... 115

APPENDIX A: EXIT TEMPERATURE VS. EXTRUSION RATIO .......................................................... 118

APPENDIX B: EXTRUSION PRESS DATABASE ............................................................................... 120

APPENDIX C: WASTE TIME ESTIMATION ..................................................................................... 123

APPENDIX D: DETAILED DRAWINGS OF EXTRUDED SHAPES QUOTED ....................................... 126

APPENDIX E: HOT EXTRUSION FBC SPREADSHEET ..................................................................... 137

REFERENCES ............................................................................................................................... 138

AUTHOR’S BIOGRAPHY ............................................................................................................... 144

Calculations:

Credit:

Jose Torre Nieto

University of Illinois at Urbana-Champaign, 2010

Related: