Related Resources: materials

Standard Columns and Heavy Weight Beam Sections per. IS 808

Engineering Standard Materials

Structural Shapes Table and Standards

Columns & Heavy Weight Beam Sections - IS 808

Indian Standard Columns and Heavy Weight Beam Sections

SC150* is mainly used for electrification

* These heavier sections in each size are obtained from the same set of rolls as the lighter sections by spreading the rolls. While ordering these sections, mass should be mentioned.

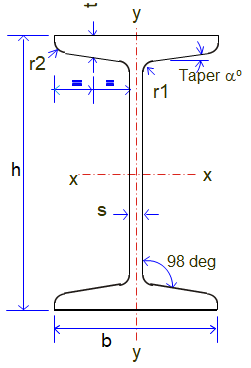

| Desig. |

Depth of Section h mm |

Width of Section b mm |

Thickness of |

Root Radius r1 mm |

Toe Radius r2 |

Flange Taper a degrees |

Depth between fillets d mm |

Second Moment of Area |

Area of Section A cm2 |

||

Web s mm |

Flange t mm |

||||||||||

Axis x-x Ix cm 4 |

Axis y-y Iy cm 4 |

25.5 |

|||||||||

ISSC 100 |

100 |

100 |

6 |

10 |

12 |

6 |

8 |

52.5 |

436 |

136 |

33.4 |

ISSC 120 |

120 |

120 |

6.5 |

11 |

12 |

6 |

8 |

69.2 |

842 |

255 |

42.4 |

ISSC 140 |

140 |

140 |

7 |

12 |

12 |

6 |

8 |

85.8 |

1475 |

438 |

47.1 |

ISSC 150* |

152 |

152 |

7.9 |

11.9 |

11.7 |

3 |

8 |

97.7 |

1927 |

554 |

53.4 |

ISSC 160 |

160 |

160 |

8 |

13 |

15 |

7.5 |

8 |

97.2 |

2424 |

695 |

64.4 |

ISSC 180 |

180 |

180 |

8.5 |

14 |

15 |

7.5 |

8 |

113.9 |

3737 |

1057 |

76.8 |

ISSC 200 |

200 |

200 |

9 |

15 |

18 |

9 |

8 |

125.3 |

5535 |

1528 |

89.8 |

ISSC 220 |

220 |

220 |

9.5 |

16 |

18 |

9 |

8 |

141.9 |

7880 |

2157 |

109 |

ISSC 250 |

250 |

250 |

10 |

17 |

23 |

11.5 |

8 |

159.1 |

12459 |

3257 |

34.5 |

ISHB 150 |

150 |

150 |

5.4 |

9 |

8 |

4 |

4 |

112 |

1456 |

432 |

38.4 |

ISHB 150* |

150 |

150 |

8.4 |

9 |

8 |

4 |

4 |

112.1 |

1513 |

435 |

42.9 |

ISHB 150* |

150 |

150 |

11.8 |

9 |

8 |

4 |

4 |

112.2 |

1579 |

440 |

47.5 |

ISHB 200 |

200 |

200 |

6.1 |

9 |

9 |

4.5 |

4 |

158.4 |

3609 |

967 |

50.6 |

ISHB 200* |

200 |

200 |

7.8 |

9 |

9 |

4.5 |

4 |

158.5 |

3695 |

972 |

54.9 |

ISHB 225 |

225 |

225 |

6.5 |

9.1 |

10 |

5 |

4 |

180.5 |

5280 |

1354 |

59.3 |

ISHB 225* |

225 |

225 |

8.6 |

9.1 |

10 |

5 |

4 |

180.6 |

5436 |

1362 |

65 |

ISHB 250 |

250 |

250 |

6.9 |

9.7 |

10 |

5 |

4 |

203.5 |

7737 |

1961 |

69.3 |

ISHB 250* |

250 |

250 |

8.8 |

9.7 |

10 |

5 |

4 |

203.5 |

7932 |

1971 |

74.8 |

ISHB 300 |

300 |

250 |

7.6 |

10.6 |

11 |

5.5 |

4 |

249.8 |

12544 |

2193 |

79.9 |

ISHB 300* |

300 |

250 |

9.4 |

10.6 |

11 |

5.5 |

4 |

249.9 |

12870 |

2203 |

85.9 |

ISHB 350 |

350 |

250 |

8.3 |

11.6 |

12 |

6 |

4 |

296 |

19162 |

2451 |

91.8 |

ISHB 350* |

350 |

250 |

10.1 |

11.6 |

12 |

6 |

4 |

296 |

19686 |

2461 |

98.7 |

ISHB 400 |

400 |

250 |

9.1 |

12.7 |

14 |

7 |

4 |

340.1 |

28086 |

2728 |

104 |

ISHB 400* |

400 |

250 |

10.6 |

12.7 |

14 |

7 |

4 |

340.1 |

28744 |

2737 |

111 |

ISHB 450 |

450 |

250 |

9.8 |

13.7 |

15 |

7.5 |

4 |

386.2 |

39204 |

2985 |

117 |

ISHB 450* |

450 |

250 |

11.3 |

13.7 |

15 |

7.5 |

4 |

386.3 |

40149 |

2994 |

|

|

Desig. |

Radius of Gyration |

Elastic Modulus |

Plastic Modulus |

Buckling Parameter u |

Torsional Index x |

Warping Constant H dm6 |

Torsional Constant Inertia J cm4 |

|||

Axis x-x rx cm |

Axis y-y ry cm |

Axis x-x Zx cm3 |

Axis y-y Zy cm3 |

Axis x-x Sx cm3 |

Axis y-y Sy cm3 |

|||||

ISSC 100 |

4.14 |

2.31 |

87.2 |

27.2 |

101 |

45.2 |

0.857 |

7.95 |

0.00275 |

10.5 |

ISSC 120 |

5.02 |

2.76 |

140 |

42.6 |

162 |

70.9 |

0.86 |

8.85 |

0.00757 |

16.2 |

ISSC 140 |

5.9 |

3.21 |

211 |

62.5 |

241 |

104 |

0.863 |

9.59 |

0.0179 |

24.2 |

ISSC 150* |

6.4 |

3.43 |

254 |

72.9 |

289 |

122 |

0.86 |

10.4 |

0.0272 |

27.3 |

ISSC 160 |

6.74 |

3.61 |

303 |

86.8 |

346 |

146 |

0.863 |

9.92 |

0.0375 |

37.5 |

ISSC 180 |

7.62 |

4.05 |

415 |

117 |

472 |

198 |

0.865 |

10.5 |

0.0728 |

51.9 |

ISSC 200 |

8.49 |

4.46 |

553 |

153 |

628 |

259 |

0.867 |

10.7 |

0.131 |

73.3 |

ISSC 220 |

9.37 |

4.9 |

716 |

196 |

810 |

333 |

0.868 |

11.1 |

0.224 |

96.5 |

ISSC 250 |

10.7 |

5.47 |

997 |

261 |

1123 |

449 |

0.872 |

11.6 |

0.442 |

141 |

ISHB 150 |

6.5 |

3.54 |

194 |

57.6 |

216 |

92.7 |

0.863 |

15 |

0.0215 |

9.77 |

ISHB 150* |

6.27 |

3.36 |

202 |

58 |

229 |

94.7 |

0.844 |

14 |

0.0216 |

12.4 |

ISHB 150* |

6.06 |

3.2 |

211 |

58.6 |

244 |

97.6 |

0.827 |

12.3 |

0.0219 |

18 |

ISHB 200 |

8.71 |

4.51 |

361 |

96.7 |

397 |

159 |

0.865 |

19.6 |

0.0882 |

14.4 |

ISHB 200* |

8.54 |

4.38 |

369 |

97.2 |

411 |

161 |

0.855 |

19 |

0.0886 |

16.4 |

ISHB 225 |

9.8 |

4.96 |

469 |

120 |

516 |

200 |

0.866 |

21.5 |

0.158 |

17.8 |

ISHB 225* |

9.58 |

4.79 |

483 |

121 |

538 |

203 |

0.853 |

20.5 |

0.159 |

21 |

ISHB 250 |

10.9 |

5.49 |

619 |

157 |

679 |

262 |

0.867 |

22.5 |

0.283 |

23.8 |

ISHB 250* |

10.7 |

5.33 |

635 |

158 |

704 |

265 |

0.856 |

21.7 |

0.285 |

27.3 |

ISHB 300 |

12.9 |

5.41 |

836 |

175 |

922 |

292 |

0.879 |

25.3 |

0.459 |

31.4 |

ISHB 300* |

12.7 |

5.25 |

858 |

176 |

957 |

295 |

0.868 |

24.4 |

0.461 |

36 |

ISHB 350 |

14.9 |

5.34 |

1095 |

196 |

1214 |

324 |

0.883 |

27.6 |

0.702 |

41.4 |

ISHB 350* |

14.6 |

5.18 |

1125 |

197 |

1262 |

328 |

0.872 |

26.6 |

0.705 |

47.7 |

ISHB 400 |

16.9 |

5.26 |

1404 |

218 |

1566 |

361 |

0.883 |

29.1 |

1.02 |

55.9 |

ISHB 400* |

16.6 |

5.12 |

1437 |

219 |

1619 |

364 |

0.873 |

28.3 |

1.03 |

62.7 |

ISHB 450 |

18.8 |

5.18 |

1742 |

239 |

1955 |

394 |

0.88 |

30.9 |

1.42 |

71.1 |

ISHB 450* |

18.5 |

5.05 |

1784 |

240 |

2022 |

398 |

0.871 |

30 |

1.42 |

79.8 |

Related: