Related Resources: pressure-vessel

Circular Flat Head Welded with Internal or External Pressure Equation and Calculator

Structural Design and Analysis

Pressure Vessel Design and Engineering

Circular Flat Head Welded with Internal or External Pressure Equation and Calculator

ALL calculators require a Premium Membership

Preview

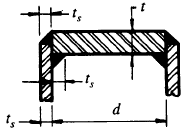

Stress in Pressure Vessel Welded Flat Head Section Seam Calculator:

Required minimum wall thickness

t = d ( C P / ( S E) )0.5

C = 0.33 tr / ts

Cmin = 0.20

Where:

P = Design pressure or max. allowable working pressure, psi

d = Inside diameter of vessel , inches

S = Rated stress value of the material

t = Minimum thickness of shell (wall) exclusive of corrosion, inches

th = Actual thickness used in actual design, inches

tr = Minimum required thickness of seamless shell for pressure, inches

ts = Actual thickness of shell, exclusive of corrosion allowance, inches

E = Weld Joint efficiency

Example Design Calculations:

P = 300 psi design pressure

E= joint efficiency

d = 24in. inside diameter of shell

s =15,000 psi maximum allowable stress value of plate

tr = 0.243 in. required thickness of seamless shell for pressure.

ts = 0.3125 in. actual thickness of shell.

C = 0.330 ( 0.234 in. / 0.3125 in. ) = 0.260

t = 24 in ( 0.26 in x 300 psi / ( 15,000 psi x 1.0 ) = 1.731 in.

Design use 1.75 in. plate

If using a thicker plate for shell, a less thick plate would be satisfactory for the head.

ts = 0.375 in. actual thickness of shell.

C = 0.330 ( 0.234 in. / 0.375 in. ) = 0.214

t = 24 in ( 0.214 in x 300 psi / ( 15,000 psi x 1.0 ) = 1.57 in.

Design use 1.625 in. plate

The shell thickness should be maintained along a distance 2 ( d ts )0.5 from the inside face of the head

2 ( 24in. 0.375 in.)0.5 = 6 in.