Axial Flow Pump Review

Axial Flow Pump Review

An axial-flow pump , or AFP, is a common type of pump that essentially consists of a propeller (an axial impeller ) in a pipe. The propeller can be driven directly by a sealed motor in the pipe or by electric motor or petrol/diesel engines mounted to the pipe from the outside or by a right-angle drive shaft that pierces the pipe.

Fluid particles, in course of their flow through the pump, do not change their radial locations since the change in radius at the entry (called 'suction') and the exit (called 'discharge') of the pump is very small. Hence the name "axial" pump.

An axial flow pump has a propeller -type of impeller running in a casing. The pressure in an AFP is developed by the flow of liquid over the blades of impeller. The fluid is pushed in a direction parallel to the shaft of the impeller, that is, fluid particles, in course of their flow through the pump, do not change their radial locations. It allows the fluid to enter the impeller axially and discharge the fluid nearly axially. The propeller of an AFP is driven by a motor.

Within Axial Flow Pumps (AFP) , the impeller pushes the liquid in a direction parallel to the pump shaft. Axial flow pumps are sometimes called propeller pumps because they operate essentially the same as the propeller of a boat. Applications include low head and high capacity pumping requirements for any fluid. The impeller of a typical axial flow pump and the flow through a radial flow pump are shown in the illustration below.

Axial Flow Pumps

Sizing design of Axial Flow Pump:

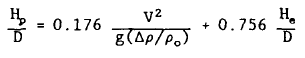

For use as a design factor, Equation I can be used to solve for the design velocity assuming a pump diameter. For large-diameter propellers normally manufactured for operation in air, the maximum design velocity should be less than about 1.0 m/sec because the propeller hib is designed for stresses related to high-speed, low-resistance operation. A good target velocity is about 0.5 to 0.8 m/sec. A propeller designed for operating in water, such as a ship's propeller, can be operated at higher velocities than the target velocity.

Equation I

Where:

The pump diameter and number of pumps required are determined by considering the flow rate needed to be pumped. The flow rate ( Q , in meters per second) is calculated by:

Q = 0.785D2V