GD&T Intermediate Geometric Dimensioning & Tolerancing Training ASME Y14.5-2009

| GD&T Intermediate Interpretation and Application Training

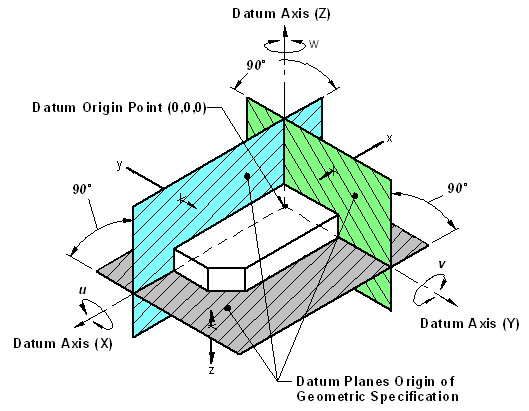

Based on ASME Y14.5 - 2009 standard, 2.5 or more (upto five) day GDT Geometric Dimensioning and Tolerancing Intermediate class. Ordered and conceptually based tolerancing concepts are presented to help “see” how ASME Y14.5 is interpreted and applied on engineering drawings of parts and assemblies. Emphasis is placed upon developing skills necessary to clearly analyze, define requirements, specify dimensional functions, datum (coordinate) locations, inspection of geometric tolerances, and tolerance boundaries and shapes of all geometric and limit tolerance concepts. The goal of this training is to ensure a common and group-wide understanding of the principles, interpretation and application of geometric dimensioning and limit tolerancing. Training is presented utilizing Power Point slides, physical models (parts), videos, white board detailing and lecture. Learners participate in individual and group exercises with trainer distributed worksheets and other documents. Audience: This Geometric Dimensioning and Tolerancing GD&T training is best for designers, mechanical engineers, quality engineers, manufacturing, dimensional inspection and others whom have had exposure to geometric dimensioning and tolerancing. Entry level engineers, designer, scientist and other professions can benefit from this training series. Typical 3 Day ASME GD&T Intermediate Training

Day 1

Day 2

Day 3

Course prices may be obtained by completing our request for quote form. Training & Reference Books Used and Available

Call for More GD&T Training Information GD&T Training Classes Overview © Copyright, by Engineers Edge, All rights reserved. Disclaimer |