Design for Manufacturability and Assembly Training DFM/DFA

Standard and Custom Seminars Available

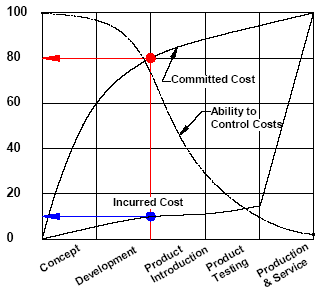

Design for manufacturability (also know as design for manufacturing) and assembly (DFM/DFA) is the application of process, method and art of creating cost effective product designs. The design stage is very important and ultimately influential in the end-product cost, quality, and time to market. Overall product lifecycle characteristics are committed at design stage. The product design is not just based on good design or engineering factors but it should consider the through-put or manufacturing as well. Course Overview and Objectives: Engineers Edge Design for Manufacturability (DFM) and Assembly (DFA):

Audience

This course is recommended for anyone involved in product design, manufacturing engineering, and manufacturing management. This includes drafters, designers, engineers, manufacturing engineers, process engineers, quality engineers, mechanical engineers and others who are involved in design, engineering and manufacturing activity. Testimonials: "For what I thought was going to be a boring seminar I sure got a lot out of the training!" "This class was helpful for evaluating and establishing component design guidelines." "Good job at changing the agenda on the fly and getting us what we needed - thanks again." "I hope you enjoyed Japan and had a good flight back to the US. I loved your DFM training last week. The class will help us get the new DFM role started here at SKK." "The instructor provided great detail explanation of individual processes. The assembly design optimization workshop was most helpful"

White Papers and GD&T Resources

Other Training & Reference Books Used and Available

Request Quote and Contact Information Copyright, by Engineers Edge, All rights reserved. Disclaimer |