Surface Roughness Conversion Chart Tables

Manufacturing Knowledge Menu

Surface Roughness Review

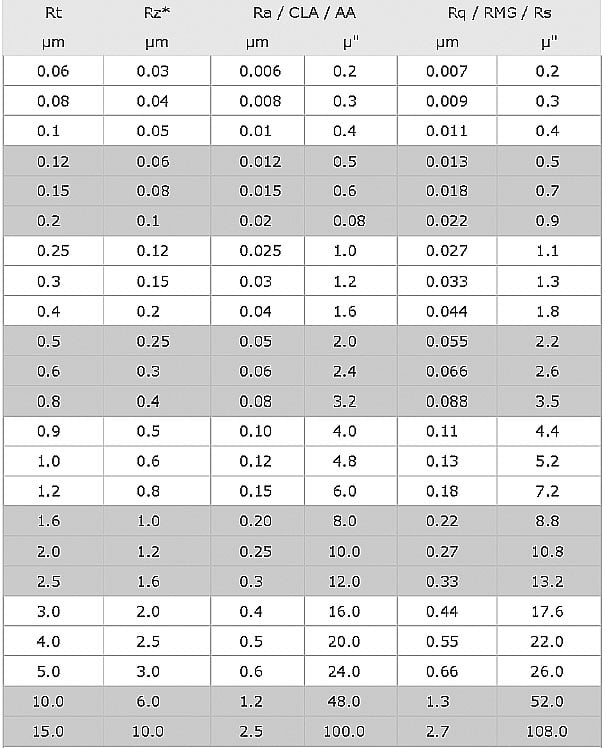

The following charts and tables convert surface finish or roughness between selected industry standard units.

Where:

Ra = Roughness, average in micro-meters & micro-inches

RMS = Root Mean Square in micro-inches

CLA = Center Line average in micro-inches

Rt = Roughness, total in microns

N = New ISO (Grade) Scale numbers

Cut-Off Length = Length required for sample.

Conversion math at bottom --

μ=0.000001m=0.001mm

μin=0.000001 in=0.0254 μ

Surface Roughness Conversion Chart |

|||||||

|---|---|---|---|---|---|---|---|

Ra micro-meters |

Ra micro-inches |

RMS |

CLA (N) |

Rt |

N |

Cut-Off Length |

|

in. |

mm |

||||||

0.025

|

1

|

1.1

|

1

|

0.3

|

1

|

0.003

|

0.08

|

0.05

|

2

|

2.2

|

2

|

0.5

|

2

|

0.01

|

0.25

|

0.1

|

4

|

4.4

|

4

|

0.8

|

3

|

0.01

|

0.25

|

0.2

|

8

|

8.8

|

8

|

1.2

|

4

|

0.01

|

0.25

|

0.4

|

16

|

17.6

|

16

|

2.0

|

5

|

0.01

|

0.25

|

0.8

|

32

|

35.6

|

32

|

4.0

|

6

|

0.03

|

0.8

|

1.6

|

63

|

69.3

|

63

|

8.0

|

7

|

0.03

|

0.8

|

3.2

|

125

|

137.5

|

125

|

13

|

8

|

0.1

|

2.5

|

6.3

|

250

|

275

|

250

|

25

|

9

|

0.1

|

2.5

|

12.5

|

500

|

550

|

500

|

50

|

10

|

0.1

|

2.5

|

25.0

|

1000

|

1100

|

1000

|

100

|

11

|

0.3

|

8.0

|

50.0

|

2000

|

2200

|

2000

|

200

|

12

|

0.3

|

8.0

|

Conversions (math):

CLA (micro inches) = Multiply Ra(µm) x 40

Rt = R a x 8.7

Rz = R a x 7.2

Rz ISO = R a x 7.6

Rmax = R a x 8.0

Rp = R a x 3.6

RPM = R a x 2.9

RMS = R a x 1.1

Example:

Ra to Rt:

1.0 micrometer Ra x 8.7 (Rt Factor) = 8.7 micrometer Rt

40 microinch Ra x 8.7 (Rt Factor) = 348 microinch Rt

|

CHINA |

UK |

USA |

GERMANY |

||||||

|

Ra |

Rz Ry |

Code |

Ra |

Code |

Ra |

Code |

Ra |

Rz |

|

|

0.008 |

0.032 |

1(0.025) |

|

1(0.025) |

|

0.01 |

0.04 |

||

|

0.01 |

0.04 |

||||||||

|

0.012 |

0.05 |

0.016 |

0.063 |

||||||

|

0.016 |

0.063 |

||||||||

|

0.02 |

0.08 |

0.025 |

0.10 |

||||||

|

0.025 |

0.10 |

||||||||

|

0.032 |

0.125 |

2(0.05) |

2(0.05) |

0.04 |

0.16 |

||||

|

0.04 |

0.16 |

||||||||

|

0.05 |

0.20 |

0.063 |

0.25 |

||||||

|

0.063 |

0.25 |

4(0.10) |

3(0.08) |

||||||

|

0.08 |

0.32 |

0.10 |

0.40 |

||||||

|

0.10 |

0.40 |

4(0.10) |

|||||||

|

0.125 |

0.50 |

8(0.2) |

5(0.125) |

0.16 |

0.63 |

||||

|

0.16 |

0.63 |

6(0.16) |

|||||||

|

0.20 |

0.80 |

8(0.2) |

0.25 |

1 |

|||||

|

0.25 |

1 |

16(0.4) |

10(0.25) |

||||||

|

0.32 |

1.25 |

13(0.32) |

0.40 |

1.60 |

|||||

|

0.40 |

1.6 |

16(0.4) |

|||||||

|

0.50 |

2 |

32(0.8) |

20(0.5) |

0.63 |

2.5 |

||||

|

0.63 |

2.5 |

25(0.63) |

|||||||

|

0.8 |

3.2 |

32(0.8) |

1 |

4 |

|||||

|

1 |

4 |

63(1.6) |

40(1) |

||||||

|

1.25 |

5 |

50(1.25) |

1.6 |

6.3 |

|||||

|

1.6 |

6.3 |

63(1.6) |

|||||||

|

2 |

8 |

125(3.2) |

80(2) |

2.5 |

10 |

||||

|

2.5 |

10 |

100(2.5) |

|||||||

|

3.2 |

12.5 |

125(3.2) |

4 |

16 |

|||||

|

4 |

16 |

250(6.3) |

160(4) |

||||||

|

5 |

20 |

200(5) |

6.3 |

25 |

|||||

|

6.3 |

25 |

250(6.3) |

|||||||

|

8 |

32 |

500(12.5) |

500(12.5) |

10 |

40 |

||||

|

10 |

40 |

||||||||

|

12.5 |

50 |

16 |

63 |

||||||

|

16 |

63 |

1000(25) |

800(20) |

||||||

|

20 |

80 |

25 |

100 |

||||||

|

25 |

100 |

1000(25) |

|||||||

|

32 |

125 |

40 |

160 |

||||||

|

40 |

160 |

||||||||

|

125 |

200 |

63 |

250 |

S |

|||||

|

63 |

250 |

||||||||

|

80 |

320 |

100 |

400 |

||||||

|

250 |

400 |

||||||||

|

160 |

630 |

||||||||

|

250 |

1000 |

||||||||

|

1600 |

|||||||||

|

2500 |

|||||||||

|

CHINA |

SWITZERLAND |

ITALY |

POLAND |

|||||||

|

Ra (μ) |

Rz Ry (μ) |

Code |

Ra (μ) |

Code |

Ra (μ) |

Ra (μ) |

Rz (μ) |

Code |

||

|

0.008 |

0.032 |

0.025 |

N1 |

0.025 |

|

0.01 |

0.05 |

|||

|

0.01 |

0.04 |

|||||||||

|

0.012 |

0.05 |

0.02 |

0.10 |

|||||||

|

0.016 |

0.063 |

|||||||||

|

0.02 |

0.08 |

|||||||||

|

0.025 |

0.10 |

0.04 |

0.20 |

|||||||

|

0.032 |

0.125 |

0.05 |

N2 |

0.05 |

||||||

|

0.04 |

0.16 |

|||||||||

|

0.05 |

0.20 |

0.08 |

0.40 |

|||||||

|

0.063 |

0.25 |

0.1 |

N3 |

0.08 |

||||||

|

0.08 |

0.32 |

|||||||||

|

0.10 |

0.40 |

0.1 |

0.16 |

0.80 |

||||||

|

0.125 |

0.50 |

0.2 |

N4 |

0.12 |

||||||

|

0.16 |

0.63 |

0.16 |

||||||||

|

0.20 |

0.80 |

0.2 |

0.32 |

1.60 |

||||||

|

0.25 |

1 |

0.4 |

N5 |

0.25 |

||||||

|

0.32 |

1.25 |

0.3 |

||||||||

|

0.40 |

1.6 |

0.4 |

0.63 |

3.20 |

||||||

|

0.50 |

2 |

0.5 |

N6 |

0.5 |

||||||

|

0.63 |

2.5 |

1.6 |

N7 |

0.6 |

||||||

|

0.8 |

3.2 |

0.8 |

1.25 |

6.30 |

||||||

|

1 |

4 |

1 |

||||||||

|

1.25 |

5 |

1.2 |

||||||||

|

1.6 |

6.3 |

1.6 |

2.5 |

10 |

||||||

|

2 |

8 |

3.2 |

N8 |

2 |

||||||

|

2.5 |

10 |

2.5 |

||||||||

|

3.2 |

12.5 |

3 |

5 |

20 |

||||||

|

4 |

16 |

6.3 |

N9 |

4 |

||||||

|

5 |

20 |

5 |

||||||||

|

6.3 |

25 |

6 |

10 |

40 |

||||||

|

8 |

32 |

12.5 |

N10 |

8 |

||||||

|

10 |

40 |

10 |

||||||||

|

12.5 |

50 |

12 |

20 |

80 |

||||||

|

16 |

63 |

25 |

N11 |

25 |

||||||

|

20 |

80 |

|||||||||

|

25 |

100 |

40 |

160 |

|||||||

|

32 |

125 |

50 |

N12 |

|

||||||

|

40 |

160 |

|||||||||

|

125 |

200 |

80 |

320 |

|||||||

|

63 |

250 |

|

||||||||

|

80 |

320 |

|||||||||

|

250 |

400 |

|

||||||||

|

|

||||||||||

|

CHINA |

JAPAN |

|||||

|

Ra (μ) |

Rz Ry (μ) |

Code |

Ra (μ) |

Rz (μ) |

Rmax (μ) |

Code |

|

0.008 |

0.032 |

(0.0125a) |

(0.05S) |

|||

|

0.01 |

0.04 |

|||||

|

0.012 |

0.05 |

|||||

|

0.016 |

0.063 |

0.05a |

0.1Z |

0.1S |

||

|

0.02 |

0.08 |

|||||

|

0.025 |

0.10 |

|||||

|

0.032 |

0.125 |

0.2Z |

0.2S |

|||

|

0.04 |

0.16 |

|||||

|

0.05 |

0.20 |

|||||

|

0.063 |

0.25 |

0.1a |

0.4Z |

0.4S |

||

|

0.08 |

0.32 |

|||||

|

0.10 |

0.40 |

|||||

|

0.125 |

0.50 |

0.2a |

0.8Z |

0.8S |

||

|

0.16 |

0.63 |

|||||

|

0.20 |

0.80 |

|||||

|

0.25 |

1 |

0.4a |

1.6Z |

1.6S |

||

|

0.32 |

1.25 |

|||||

|

0.40 |

1.6 |

|||||

|

0.50 |

2 |

0.8a |

3.2Z |

3.2S |

||

|

0.63 |

2.5 |

|||||

|

0.8 |

3.2 |

|||||

|

1 |

4 |

1.6a |

6.3Z |

6.3S |

||

|

1.25 |

5 |

|||||

|

1.6 |

6.3 |

|||||

|

2 |

8 |

3.2a |

12.5Z |

12.5S |

||

|

2.5 |

10 |

|||||

|

3.2 |

12.5 |

|||||

|

4 |

16 |

6.3a |

(18Z) |

(18S) |

||

|

5 |

20 |

25Z |

25S |

|||

|

6.3 |

25 |

|||||

|

8 |

32 |

12.5a |

35Z |

35S |

||

|

10 |

40 |

50Z |

50S |

|||

|

12.5 |

50 |

|||||

|

16 |

63 |

25a |

(70Z) |

(70S) |

||

|

20 |

80 |

|||||

|

25 |

100 |

100Z |

100S |

|||

|

32 |

125 |

(50a) |

140Z |

140S |

S |

|

|

40 |

160 |

200Z |

200S |

|||

|

125 |

200 |

|||||

|

63 |

250 |

(100a) |

280Z |

280S |

||

|

80 |

320 |

400Z |

400S |

|||

|

250 |

400 |

|||||

|

560Z |

560S |

|||||

| Parameter | Factor |

| Rt | 8.7 |

| Rz | 7.2 |

| Rz ISO | 7.6 |

| Rmax | 8.0 |

| Rp | 3.6 |

| RPM | 2.9 |

| RMS | 1.1 |

Surface Roughness Value Equivalents

The Waviness is the measure of surface irregularities with a spacing greater than that of surface roughness. These usually occur due to warping , vibrations , or deflection during machining.

-

ASME B46.1

-

ASME Y14.36M - 1996 Surface Texture Symbols

-

ISO 468:1982 “Surface roughness — parameters. Their values and general rules for specifying requirements.”

-

ISO 4287:1997 “Surface texture: Profile method — Terms, definitions and surface texture parameters.”

-

ISO 4288:1996 “Surface texture: Profile method — Rules and procedures for the assessment of surface texture.” Includes specifications for precision reference specimens, and roughness comparison specimens, and establishes requirements for stylus-type instruments.”

-

ISO 8785:1998 “Surface imperfections — Terms, definitions and parameters.”

-

ISO 10135-1:CD “Representation of parts produced by shaping processes — Part 1: Molded parts.”

Link to this Webpage:

© Copyright 2000 -

2024, by Engineers Edge, LLC

www.engineersedge.com

All rights reserved

Disclaimer |

Feedback

Advertising

| Contact