Related Resources: spring material

Extension Spring Normal Load Tolerances load / force Specifications

Extension Spring Normal Load Tolerances load / force Specifications

Most extension springs are specified with initial tension, which is an internal force that holds the coils tightly together. Unlike a compression spring, which has zero load at zero deflection, an extension spring can have a preload at zero deflection.

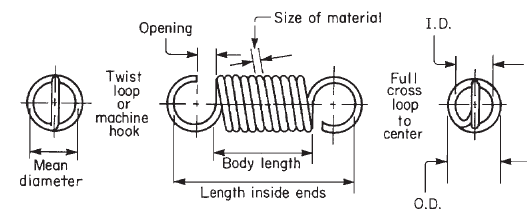

The two most common loops or hooks for extension springs are the twist loop and the cross loop. These loops are made with standard looping tools and so should be specified whenever possible to minimize cost. If required by the application, many special types of extension-spring loops are offered by the spring industry at additional cost.

Where:

D = Mean coil diameter (in)

d = Wire diameter (in)

Normal (typical) Load Tolerances for Extension Springs, ± Percent of Load

Normal Load Tolerances for Extension Springs, Percent of Load

|

Index

D/d |

Free length

deflection L/F |

Wire diameter, in

|

|||||

|

0.015

|

0.022

|

0.032

|

0.044

|

0.062

|

0.092

|

||

|

4

|

12

|

20.0

|

18.5

|

17.6

|

16.9

|

16.2

|

15.5

|

|

8

|

18.5

|

17.5

|

16.7

|

15.8

|

15.0

|

14.5

|

|

|

6

|

16.8

|

16.1

|

15.5

|

14.7

|

13.8

|

13.2

|

|

|

4.5

|

15.0

|

14.7

|

14.1

|

13.5

|

12.6

|

12.0

|

|

|

2.5

|

13.1

|

12.4

|

12.1

|

11.8

|

10.6

|

10.0

|

|

|

1.5

|

10.2

|

9.9

|

9.3

|

8.9

|

8.0

|

7.5

|

|

|

0.5

|

6.2

|

5.4

|

4.8

|

4.6

|

4.3

|

4.1

|

|

|

6

|

12

|

17.0

|

15.5

|

14.6

|

14.1

|

13.5

|

13.1

|

|

8

|

16.2

|

14.7

|

13.9

|

13.4

|

12.6

|

12.2

|

|

|

6

|

15.2

|

14.0

|

12.9

|

12.3

|

11.6

|

10.9

|

|

|

4.5

|

13.7

|

12.4

|

11.5

|

11.0

|

10.5

|

10.0

|

|

|

2.5

|

11.9

|

10.8

|

10.2

|

9.8

|

9.4

|

9.0

|

|

|

1.5

|

9.9

|

9.0

|

8.3

|

7.7

|

7.3

|

7.0

|

|

|

0.5

|

6.3

|

5.5

|

4.9

|

4.7

|

4.5

|

4.3

|

|

|

12

|

15.8

|

14.3

|

13.1

|

13.0

|

12.1

|

12.0

|

|

|

8

|

15.0

|

13.7

|

12.5

|

12.1

|

11.4

|

11.0

|

|

|

6

|

14.2

|

13.0

|

11.7

|

11.2

|

10.6

|

10.0

|

|

|

8

|

4.5

|

12.8

|

11.7

|

10.7

|

10.1

|

9.7

|

9.0

|

|

2.5

|

11.2

|

10.2

|

9.5

|

8.8

|

8.3

|

7.9

|

|

|

1.5

|

9.5

|

8.6

|

7.8

|

7.1

|

6.9

|

6.7

|

|

|

0.5

|

6.3

|

5.6

|

5.0

|

4.8

|

4.5

|

4.4

|

|

|

12

|

14.8

|

13.3

|

12.0

|

11.9

|

11.1

|

10.9

|

|

|

8

|

14.2

|

12.8

|

11.6

|

11.2

|

10.5

|

10.2

|

|

|

6

|

13.4

|

12.1

|

10.8

|

10.5

|

9.8

|

9.3

|

|

|

10

|

4.5

|

12.3

|

10.8

|

10.0

|

9.5

|

9.0

|

8.5

|

|

2.5

|

10.8

|

9.6

|

9.0

|

8.4

|

8.0

|

7.7

|

|

|

1.5

|

9.2

|

8.3

|

7.5

|

6.9

|

6.7

|

6.5

|

|

|

0.5

|

6.4

|

5.7

|

5.1

|

4.9

|

4.7

|

4.5

|

|

|

12

|

14.0

|

12.3

|

11.1

|

10.8

|

10.1

|

9.8

|

|

|

8

|

13.2

|

11.8

|

10.7

|

10.2

|

9.6

|

9.3

|

|

|

6

|

12.6

|

11.2

|

10.2

|

9.7

|

9.0

|

8.5

|

|

|

12

|

4.5

|

11.7

|

10.2

|

9.4

|

9.0

|

8.4

|

8.0

|

|

2.5

|

10.5

|

9.2

|

8.5

|

8.0

|

7.8

|

7.4

|

|

|

1.5

|

8.9

|

8.0

|

7.2

|

6.8

|

6.5

|

6.3

|

|

|

0.5

|

6.5

|

5.8

|

5.3

|

5.1

|

4.9

|

4.7

|

|

|

12

|

13.1

|

11.3

|

10.2

|

9.7

|

9.1

|

8.8

|

|

|

8

|

12.4

|

10.9

|

9.8

|

9.2

|

8.7

|

8.3

|

|

|

6

|

11.8

|

10.4

|

9.3

|

8.8

|

8.3

|

7.7

|

|

|

14

|

4.5

|

11.1

|

9.7

|

8.7

|

8.2

|

7.8

|

7.2

|

|

2.5

|

10.1

|

8.8

|

8.1

|

7.6

|

7.1

|

6.7

|

|

|

1.5

|

8.6

|

7.7

|

7.0

|

6.7

|

6.3

|

6.0

|

|

|

0.5

|

6.6

|

5.9

|

5.4

|

5.2

|

5.0

|

4.8

|

|

|

12

|

12.3

|

10.3

|

9.2

|

8.6

|

8.1

|

7.7

|

|

|

8

|

11.7

|

10.0

|

8.9

|

8.3

|

7.8

|

7.4

|

|

|

6

|

11.0

|

9.6

|

8.5

|

8.0

|

7.5

|

7.1

|

|

|

16

|

4.5

|

10.5

|

9.1

|

8.1

|

7.5

|

7.2

|

6.8

|

|

2.5

|

9.7

|

8.4

|

7.6

|

7.0

|

6.7

|

6.3

|

|

|

1.5

|

8.3

|

7.4

|

6.6

|

6.2

|

6.0

|

5.8

|

|

|

Index D/d |

Free length deflection L/F |

Wire diameter, in |

|||||

|

0.092 |

0.125 |

0.187 |

0.250 |

0.375 |

0.437 |

||

|

4 |

12 |

15.5 |

15.0 |

14.3 |

1 3.8 |

13.0 |

12.6 |

|

8 |

14.5 |

14.0 |

13.2 |

12 .5 |

11.5 |

11.0 |

|

|

6 |

13.2 |

12.7 |

11.8 |

11 .2 |

9.9 |

9.4 |

|

|

4.5 |

12.0 |

11.5 |

10.3 |

9.7 |

8.4 |

7.9 |

|

|

2.5 |

10.0 |

9.1 |

8.5 |

8. 0 |

6.8 |

6.2 |

|

|

1.5 |

7.5 |

7.0 |

6.5 |

6.1 |

5.3 |

4.8 |

|

|

0.5 |

4.1 |

4.0 |

3.8 |

3.6 |

3 .3 |

3.2 |

|

|

6 |

12 |

13.1 |

12.7 |

12.0 |

11.5 |

11.2 |

10.7 |

|

8 |

12.2 |

11.7 |

11.0 |

10 .5 |

10.0 |

9.5 |

|

|

6 |

10.9 |

10.7 |

10.0 |

9. 4 |

8.8 |

8.3 |

|

|

4.5 |

10.0 |

9.6 |

9.0 |

8 .3 |

7.6 |

7.1 |

|

|

2.5 |

9.0 |

8.5 |

7.9 |

7.2 |

6.2 |

6.0 |

|

|

1.5 |

7.0 |

6.7 |

6.4 |

6.0 |

4 .9 |

4.7 |

|

|

0.5 |

4.3 |

4.1 |

4.0 |

3.7 |

3 .5 |

3.4 |

|

|

12 |

12.0 |

11.5 |

10.8 |

10.2 |

10.0 |

9.5 |

|

|

8 |

11.0 |

10.6 |

10.1 |

9. 4 |

9.0 |

8.6 |

|

|

6 |

10.0 |

9.7 |

9.3 |

8.6 |

8.1 |

7.6 |

|

|

8 |

4.5 |

9.0 |

8.7 |

8.3 |

7.8 |

7.2 |

6.6 |

|

2.5 |

7.9 |

7.7 |

7.4 |

6.9 |

6.1 |

5.6 |

|

|

1.5 |

6.7 |

6.5 |

6.2 |

5.8 |

4 .9 |

4.5 |

|

|

0.5 |

4.4 |

4.2 |

4.1 |

3.9 |

3 .6 |

3.5 |

|

|

12 |

10.9 |

10.5 |

9.9 |

9. 3 |

9.2 |

8.8 |

|

|

8 |

10.2 |

9.7 |

9.2 |

8.6 |

8.3 |

8.0 |

|

|

6 |

9.3 |

8.9 |

8.6 |

8.0 |

7.6 |

7.2 |

|

|

10 |

4.5 |

8.5 |

8.1 |

7.8 |

7.3 |

6.8 |

6.4 |

|

2.5 |

7.7 |

7.3 |

7.0 |

6.5 |

5.9 |

5.5 |

|

|

1.5 |

6.5 |

6.3 |

6.0 |

5.6 |

5 .0 |

4.6 |

|

|

0.5 |

4.5 |

4.3 |

4.2 |

4.0 |

3 .8 |

3.7 |

|

|

12 |

9.8 |

9.5 |

9.0 |

8.5 |

8.2 |

7.9 |

|

|

8 |

9.3 |

8.9 |

8.4 |

7.9 |

7.5 |

7.2 |

|

|

6 |

8.5 |

8.2 |

7.9 |

7.4 |

6.9 |

6.4 |

|

|

12 |

4.5 |

8.0 |

7.6 |

7.2 |

6.8 |

6.3 |

5.8 |

|

2.5 |

7.4 |

7.0 |

6.6 |

6.1 |

5.6 |

5.2 |

|

|

1.5 |

6.3 |

6.1 |

5.7 |

5.4 |

4 .8 |

4.5 |

|

|

0.5 |

4.7 |

4.5 |

4.3 |

4.2 |

4 .0 |

3.3 |

|

|

12 |

8.8 |

8.4 |

8.1 |

7.6 |

7.2 |

7.0 |

|

|

8 |

8.3 |

8.0 |

7.6 |

7.2 |

6 .8 |

6.4 |

|

|

6 |

7.7 |

7.5 |

7.2 |

6.8 |

6 .3 |

5.9 |

|

|

14 |

4.5 |

7.2 |

7.0 |

6.7 |

6.3 |

5.8 |

5.4 |

|

2.5 |

6.7 |

6.5 |

6.2 |

5.7 |

5.2 |

5.0 |

|

|

1.5 |

6.0 |

5.8 |

5.5 |

5.2 |

4.7 |

4.5 |

|

|

0.5 |

4.8 |

4.6 |

4.4 |

4.3 |

4 .2 |

4.0 |

|

|

12 |

7.7 |

7.4 |

7.2 |

6.8 |

6.3 |

6.1 |

|

|

8 |

7.4 |

7.2 |

6.8 |

6.5 |

6 .0 |

5.7 |

|

|

6 |

7.1 |

6.9 |

6.5 |

6.2 |

5. 7 |

5.4 |

|

|

16 |

4.5 |

6.8 |

6.5 |

6.2 |

5.8 |

5.3 |

5.1 |

|

2.5 |

6.3 |

6.1 |

5.7 |

5.4 |

4 .9 |

4.7 |

|

|

1.5 |

5.8 |

5.6 |

5.3 |

5.1 |

- |

- |

|

Related

- Tolerances, Engineering Design & Limits & Fits

- Belleville Spring Washer Equation and Calculator

- Spring Terminology and Definitions

- Helical Compression Spring Design Equations and Calculator

- Coil Spring Engineering Design Application

- Constant Force Spring Design and Equations

- Morrison's Spring Tables Design Reference

- Leaf Spring Design and Engineering Strength of Materials

- Helical Compression Spring Critical Frequency Critical Frequency Formula and Calculator

- Compression Spring Assembly Operating Life and Reliability Equations and Calculator