Related Resources: mechanical-tolerances

Forging Tolerances Straightness Flatness and Center-to-Center

Tolerances, Engineering Design & Limits & Fits

Steel Die Forging Tolerances for straightness, flatness and tolerances for center-to-center dimensions

Drop and vertical press forgings

Tolerances for straightness and flatness are obtained from the upper part of the table calculator by referring to the appropriate horizontal line for grade F or grade E, whichever is required, and by reading the tolerance under the vertical column heading for the dimension concerned.

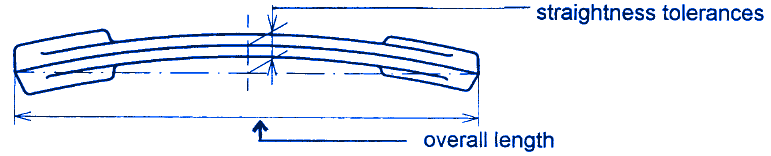

Application of Straightness and flatness tolerances

Straightness tolerances relate to deviations of center lines from the specified contour.

Flatness tolerances relate to deviations of surfaces from the specified contour.

Straightness and flatness tolerances are to be found from the table calculator according to the greatest length or greatest width dimension of the forging.

When straightness tolerances or flatness tolerances are required, this shall be indicated on the agreed forging drawing.

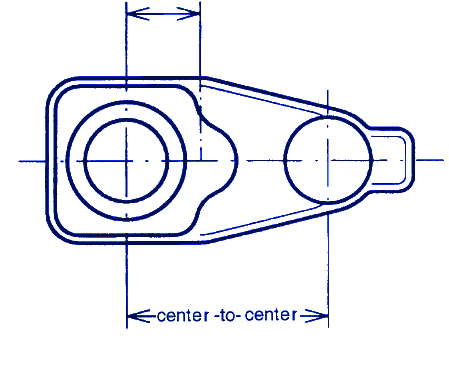

Tolerances for center-to-centrer dimensions

Dimensions to which center-to-center tolerances are applicable

In other instances center-to-center tolerances, if required either by the purchaser or the supplier, shall be negotiated before the commencement of production. Center-to-center tolerances shall be applied independently of, and in addition to, any other tolerances.

Reference:

EN 10243-1 Steel die forgings -

Tolerances on

dimensions

Part 1: Drop and vertical press forgings

Related:

- Standard Tolerances for Drop Forgings

- Forging Manufacturing Definitions and Terms

- Forging Manufacturing and Design | Forging Die Mechanical Tolerances

- Design For Forging Manufacturing Considerations

- Improved durability for forging dies | Engineering News

- ASTM A694 Forging

- Design for Manufacturability and Assembly Resources

- Design for Producibility