Related Resources: mechanical-tolerances

Thickness and Ejector Marks Tolerance Calculator Grade F Forgings

Tolerances, Engineering Design & Limits & Fits

Design for Manufacturability and Assembly Resources

Thickness and Ejector Marks Tolerance Calculator Grade F per. EN-10243-1 for Non-Circular Forgings

Thickness tolerances govern permissible variations in any dimension which crosses the die line. All

variations in thickness, due to die-closure, die-wear and shrinkage are included in the thickness tolerances. The characteristics of the forging process require that, for any given forging, all tolerances for thickness

dimensions are uniform.

Information required in determining forging tolerances

Tolerances for thickness, based on the greatest dimension of thickness, are obtained from the appropriate table for the grade required by the same method as that described above for length, width and height tolerances

To determine the tolerances applicable to a given forging the following information is required in addition to the dimensions of the forging:

- mass of forging;

- shape of die line;

- category of steel used;

- shape complexity factor;

- type of dimension.

Note: Tolerances are 2/3 and 1/3 (rounded values). Minus and plus signs, given in the table above, are applicable to external dimensions. For internal dimensions reverse the values.

The shape complexity factor takes account of the fact that in forging thin sections and branched components, as compared to components having simple compact shapes, larger dimensional variations occur which are attributable to different rates of shrinkage, higher shaping forces and higher rates of die wear.

Eq. 1

Shape complexity factor

S = mf / mes

Eq. 2

Non-Circular forging enveloping shape

mes = l · b · h · p

where

mf = mass forging

mes = Mass enveloping shape See figures 1 and 2

ρ = density (steel ~ 0.00785 g/mm3);

h = enveloping length;

l = enveloping length dimension;

b = enveloping width dimension;

h = enveloping height dimension

v = volume of enveloping shape

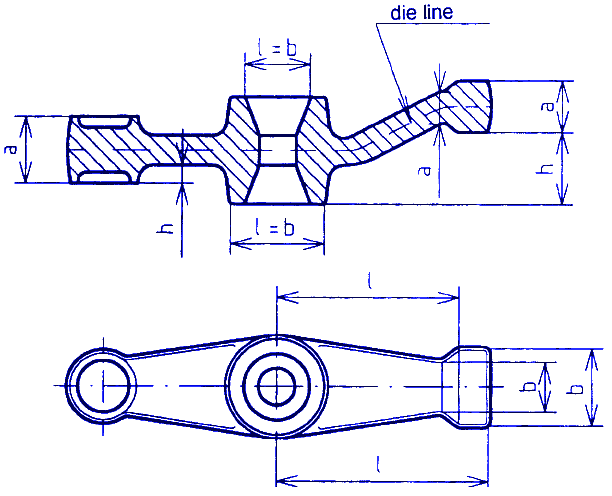

Enveloping shapes of non-circular forgings

Figure 1

Figure 1, Type of forging dimensions

l = dimensions of length in one die;

b = dimensions of width in one die;

h = dimensions of height in one die;

a = dimensions of thickness across die line.

The resulting shape complexity factor is determined as falling within one of the following categories:

S4: Up to and including 0,16;

S3: Above 0,16 up to and including 0,32;

S2: Above 0,32 up to and including 0,63;

S1: Above 0,63 up to and including 1.

Category of steel used

The type of steel symbol used takes account of the fact that steels of high carbon and high alloy content are more difficult to deform and cause higher die wear than do steels with lower carbon content and lower alloying elements.

The category of steel used is determined as being within one of the following:

- Group M1: Steel with carbon content not more than 0,65 % and total of specified alloying elements (Mn, Ni, Cr, Mo, V, W) not more than 5 % by mass;

- Group M2: Steel with carbon content above 0,65 % or total of specified alloying elements (Mn, Ni, Cr, Mo, V, W) above 5 % by mass.

To determine the category in which a steel belongs, the maximum permitted content of the elements in the steel specification shall be the values used.

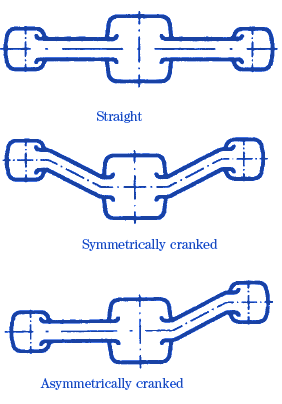

Shape of die line

Figure 3 Shape of Die

Reference:

EN 10243-1 Steel die forgings Tolerances on dimensions, Part 1: Drop and vertical press forgings

Alternatively: BS EN 10243-1, Steel die forgings Tolerances on dimensions, Part 1: Drop and vertical press forgings

Related

- Circular Forgings Normal Tolerance Calculator per. EN-10243-1

- Circular Forgings Tight Tolerance Calculator per. EN-10243-1

- Forgings Normal Tolerance Calculator per. EN-10243-1

- Forgings Tolerances for fillet , edge radii, burrs and sheared ends

- Forging Tolerances Straightness Flatness and Center-to-Center

- Standard Tolerances for Drop Forgings

- Forging Manufacturing Definitions and Terms

- Forging Manufacturing and Design | Forging Die Mechanical Tolerances

- Design For Forging Manufacturing Considerations

- ASTM A694 Forging

- BS 4620 Hot Forged Snap Head Rivet